If you’re like most large manufacturers, the management of supplier goods is a complex process with multiple stakeholders.

You have Planning that drives forecast and production scheduling, and Procurement that purchases materials from vendors based on those demand forecasts. Operations oversees the flow of incoming goods in the production line, and then Warehouse Management receives inbound shipments and moves them into inventory until ready for use. While the titles and roles may vary among organizations, the basic supplier workflow is generally the same.

Where it gets messy and you experience significant costs in time and money is the physical handoff from your supplier. Essentially, when the box hits the dock.

That’s why it’s not unusual to see pallets and pallets of supplier goods stacked up in receiving waiting to be sorted out and relabeled. If things go right, you or a 3PL partner will spend several days creating and printing new labels, which drives the need for additional buffer inventory. If things go wrong, a chain reaction of inefficiency can occur:

You can end up spending hundreds of thousands, even millions of dollars reconciling supplier goods and driving up inventory costs. Ask yourself this: If it takes weeks for supplies to travel thousands of miles from Asia to your dock, why does it take another several days for the same supplies to move a few hundred feet to be properly processed for your operation?

Consider the label. Think about it — the label connects the supplier’s intent to your ERP and, equally important, to the part itself. What if you could control the labeling outside your four walls so that shipments from suppliers and other trading partners were labeled with the information you required? Your data, your barcodes, your instructions, your process?

Thanks to new advancements and the adoption of cloud-based Enterprise Labeling, you can make this a reality. By using data directly from your ERP and merging it with supplier actions, you ensure that inbound materials are labeled and formatted the right way — your way, securely. In addition, you can track goods with unprecedented visibility to respond faster and smarter to fluctuations in supply and demand.

Read on and discover how cloud-based labeling significantly improves your supplier transactions. Using a simple formula, you can calculate potential savings when you eliminate the relabeling process and reduce costly inventory. You may be surprised at the results when you plug in some of your own numbers. Take a look, and share with other members of your supply chain team.

Today’s manufacturing and supply chain operations are so complex and so intertwined that the lines of communication can become blurred, especially when working with trusted partners outside your organization. There are so many more people involved with transactions leading to more chances of error — unless the label is right. Nowhere is this more evident than in the ordering and subsequent receiving of goods and materials from suppliers.

Typically, the partner or supplier will receive an electronic notification of the order along with a set of shipment build instructions that dictate the labeling requirement. Labeling instructions may also come via a separate SOP. Order terms and a delivery date are then negotiated between supplier and Procurement. An AdvancedShipping Notice (ASN), via EDI or XML format, will come from the supplier notifying the manufacturer of impending deliveries, including shipping date, quantities, physical characteristics, and a PO number.

Unless specified ahead of time by Procurement in collaboration with other stakeholders — again, Procurement is often the primary conduit with the supplier — the ASN becomes more of a financial document where it can be received by the company’s ERP to initiate and complete payment.

While many ASN templates provide fields to include additional information from the supplier, including batch and lot numbers — data that is valuable to Warehouse Management, Materials Handling, and Planning — they are often left blank. As a result, you won’t find them on the corresponding pallet and carton labels created, printed, and applied by the supplier. What arrives at the receiving dock may satisfy Procurement’s requirements, but those next in line in the supply chain don’t always see everything they need.

What comes next is a surprisingly common, generally accepted practice of relabeling inbound materials.

You can always count on inbound materials to be labeled. Unfortunately, the accuracy and usefulness of that label is often in the hand of the supplier with direction from the manufacturer. Depending on the manufacturer and its procurement model, what’s on the label can determine how fast and how efficient the next department will process the materials. For example, Marketing may require logos, Regulatory often requires graphics or warnings, and Materials Handling could really use a good product ID barcoded. All of these requirements could be in guidelines that were never communicated to the supplier or the supplier is “working on it.”

That’s why at so many manufacturers’ receiving docks, regardless of industry, you’ll see pallets of inbound materials waiting to be inspected, identified, and relabeled before they can move to the production line or be put away.

Strong labeling standards will have already been established with manufacturers sharing label guidelines in the form of a PDF with the right formatting that suppliers can replicate. This, of course, assumes suppliers are using the most recent template and have access to all of the relevant information from the manufacturer including any new regulatory requirements. However, is this enough? Does the supplier, for example, know if the part being shipped is short on the production line? Do they have your part number or your preferred put away location?

Additionally, in this scenario can you duplicate the process with multiple suppliers and do it quickly and accurately? Bringing on new trade partners and furnishing them with the same critical label data and instructions can slow down your upstream efficiency — especially if it requires a significant amount of interdepartmental communication.

There’s a new requirement like the need to include the recent country of origin or a simple batch number on the label. Both of which require an update from your suppliers. Are you prepared for the relabeling activity that ensues until the change is communicated and put into production by your suppliers? You can assign a team of three or four people to create, print, and apply labels to supplier goods. Or you might choose to work with a 3PL partner to relabel materials. Either way, there are exorbitant time, labor, materials, and inventory costs associated with this exercise.

And what if this was a key part that was running short in production? Can you afford the delays or disruptions further downstream?

A mistake happens because a label is missing data that’s been required for months or worse critical regulatory information that could result in fines or worse. Materials are received to the wrong PO, or worse, received under the wrong part number.

Chaos ensues as now your inventory positions are wrong for two parts, and Planning needs to scramble to expedite the “right” materials. At the same time, warehouse and receiving managers are looking to resolve the issue through time-consuming cycle counts and stepped up inspections of inbound shipments. Accounts Payable must correct the invoice to PO once the problem has been identified. And let’s not forget the finger pointing.

In this scenario, your business suffers in many ways: lead times increase to cover for this problem in the future, production could be shut down, inventory costs skyrocket, and time to market can be delayed or goods can be turned away at the border. Not a good situation, and yet one that many manufacturers have to deal with all too frequently.

Some supply chain practices are so commonplace that companies don’t always consider the impact to their bottom line. Especially if it’s something like the relabeling of supplier goods that’s so entrenched in the “way things are done” that it goes unnoticed. But there is a method to calculate the hard, tangible dollars spent on relabeling, and it’s a formula that has worked for other manufacturers. And when you do the math, it really is eye opening.

If you perform relabeling in-house, you simply take the number of full-time employees (FTEs) dedicated to relabeling, multiply that by their salary or the per-hour cost spent on relabeling, and times that figure by the number of plants that relabel inbound materials (assuming the same number of employees take about the same amount of time to relabel). Then you enter the number of labels that need to be printed and multiply that by the cost per label. That’s your total material costs

One customer calculated that they spent $2.1M just on relabeling of supplier materials.

If you use a 3PL partner to relabel supplier goods as part of their other responsibilities, it’s even easier to figure out the costs as it’s probably listed in your invoice as a materials handling charge. Ask them to provide a detailed breakdown of the cost and you may discover comparable numbers.

Now every manufacturer is different, but we’ve seen similar results working with customers in a wide range of industries. What’s particularly sobering is that this only scratches the surface into the extended costs associated with the receiving of supplier goods. When you take into account the impact on inventory positions where delays in receiving materials adds days to the inventory you must keep on hand, the costs skyrocket into the multi-millions.

With mandates from the top to reduce costs, more manufacturers are becoming aware of inefficiencies in the supplier hand-off and are looking for solutions. Here are the three most common approaches:

With this approach, manufacturers will create a PDF with detailed instructions on how they want suppliers to format labels on inbound shipments. Guides often include required data fields, special handling language, and even sample labels for the supplier to follow. The problem here is the dependency on the supplier to actually adopt and implement the guidelines. Many are slow to get up to speed with such stipulations, and it is hard to enforce. Are you really going to refuse shipment of a much-needed part or component if the box is labeled incorrectly? And if you ever change guidelines — which happens frequently like with the recent country of origin requirement or if regulatory requirements evolve — it’s difficult to get the supplier to comply in a timely fashion.

A good number of manufacturers try to make it easier on their supplier and furnish them with the labels they want on materials. But isn’t this another form of relabeling, just putting the burden on your team earlier in the process? There is also risk with this approach as you’re leaving it up to the supplier to store labels in a secure place. And what’s the guarantee that they will be applied correctly to the right shipments? Again, the dependency on the supplier to consistently meet your requirements is too great to fully embrace this alternative. Also, bulk purchases of labels can become obsolete with the next change from Marketing or an updated regulation. These excess labels become unusable and have cost associated with disposal.

As mentioned earlier, ASN transactions provide fields for manufacturers to work with suppliers and provide the requisite data needed by all groups to include materials handling or warehouse management. This isn’t a silver bullet, however, as not all suppliers have this capability or are willing to support it. Less sophisticated suppliers may provide top-level data only, leaving off the critical pallet contents needed for proper receiving. Unless you can be certain that your supplier is fully on-board with matching data between the ASN and printed label — and that this data aligns with your own internal systems and downstream process — there is risk that you’ll experience costly mis-signaling.

Rather than putting the burden on the supplier to adopt cumbersome label guidelines or new technology that may or may not fit with their process (or budget), why not take back control and provide them with the accurate labels and data you need when they’re ready to ship — easily and securely? Cloud-based Enterprise Labeling makes it faster and easier to produce labels at your suppliers and other partners to ensure accuracy, eliminate relabeling, and reduce dock-to-stock time. And that’s just for starters.

Many manufacturers are already relying on labeling to drive measurable gains within their “four walls.” The tight integration with existing enterprise applications like ERP, PLM, WMS, and other systems ensures that the data on the label is the most current and enables companies to automate the labeling process within these applications. By standardizing and centralizing on a single automated cloud-based labeling platform, companies can share templates with internal and external teams to ensure that the right data is put on the right label at the right time. This approach also simplifies approval workflows, reduce the number of templates to manage, and keeps up with changing requirements without duplicating efforts.

Now imagine simply extending controlled access of labeling process to your trading partners such as suppliers and 3PLs. Thanks to breakthrough, browser-based technology, you can allow suppliers to securely access, update, and print your labels locally with the exact information and data your downstream process requires.

And because the data is coming directly from your ERP and other sources of truth, you can be confident that the label will capture the latest information, whether it’s regulatory, branding, or specific customer requirements — and all in real time.

Importantly, from an implementation and execution phase, there’s minimal effort required of your suppliers. They have to create and print pallet and carton labels anyway; now they simply access your system to print your labels in your format according to corporate standards. In addition, this new approach to supplier labeling complements and greatly enhances the existing ASN/EDI process they’re currently using by sharing valuable data that can be cross-referenced on the ASN. They can even leverage the label data to help create the ASN, if they wish.

The short- and long-term benefits of this approach are many.

First and foremost, when you push labeling to your suppliers using your data, your instructions, your downstream processes — even your branding — you avoid costly relabeling altogether. Remember the example from earlier: this alone has saved companies upwards of $2M - $3M in labor and materials.

Now you can move product from dock to stock in record time. No more confusion or uncertainty when supplier shipments arrive. No more manual intervention which slows you down and can result in costly mistakes. You also help limit the number of cycle counts and inspections required by warehouse management or operations. This leads to an even greater benefit.

Because you can eliminate delays in receiving (not to mention labeling errors) and move materials swiftly as part of your downstream process, you don’t need to store as much buffer or safety stock. If you reduce the required inventory by just a shift or two, you could save millions in warehousing costs.

From a planning and receiving perspective, you now have visibility into when labels are printed by the supplier to better estimate arrival of goods — even before the ASN. As you gain insight into supplier behavior based on how and when they use your templates, you can revise safety stock calculations to reduce inventory even more. Visibility=confidence=reduced stocking levels.

As needs change in operations, you can actually push and pull supplier orders to adjust the delivery schedule. Say, for example, you have a sudden shortage of a certain part as reflected in the ERP, and you notice that the supplier hasn’t printed labels yet. You can alert them, add to the order if needed, and even put special instructions on the label for receiving to rush the parts to production. Calls to the suppliers can be more precise allowing execution to begin sooner.

With cloud-based labeling, you can start injecting control over how the supplier is managing transactions. Set up rules that enable a supplier to only print labels tied to a particular time fence. This helps prevent a supplier from dumping inventory at the end of the year. You can also FIFO the POs. No more “cherry picking” POs by suppliers.

The secure push of labels greatly benefits how you work with smaller suppliers that don’t use an ASN/EDI process. Procurement, Planning, and Warehouse Management can have one view into inbound shipments without using cumbersome faxes, spreadsheets and other methods. Ultimately, you’ll have full visibility and control over what your suppliers print and when.

With enhanced visibility into supplier labels and their shipping methods, you can see which orders were expedited. Was it your request or the supplier’s? Now you have the proof to reconcile any transportation costs associated with delays on their end.

And because you design and own all the supplier labels — from the carton to the pallet to the truck — you have granular detail on your materials location every step of the way. This helps you adopt a management by exception process for more precise control based on your specific needs.

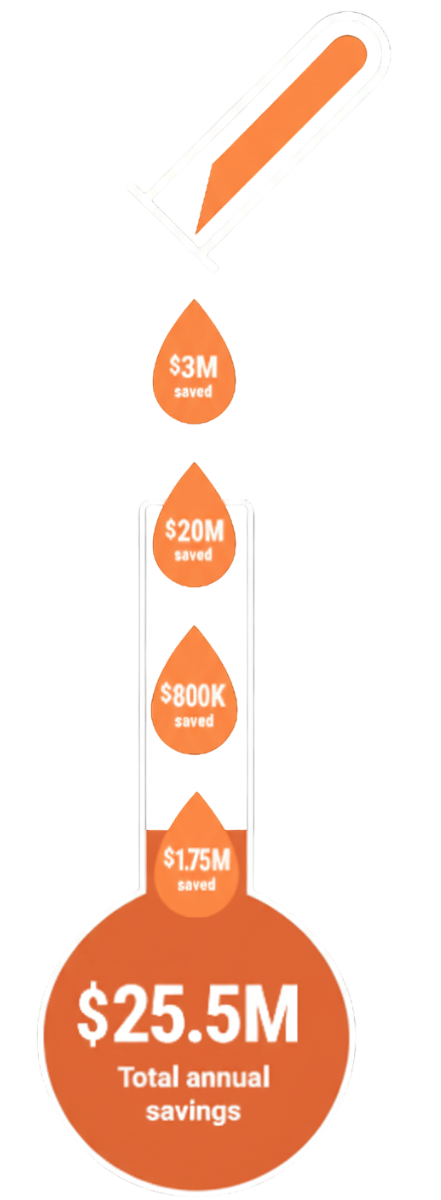

The following example shows the calculations of a large chemical company as they were weighing the value of implementing a cloudbased Enterprise Labeling solution. Like many manufacturers they had come to accept the relabeling of supplier goods as a necessary cost of doing business. It was only after they delved a little deeper and started doing the math that they realized how much they could actually save. By eliminating relabeling and gaining new visibility into inbound materials, this company could potentially save almost $25M annually.

Bottom-line improvements are critical to achieve performance goals. The ability to extend your process on to your suppliers can provide compelling results. Your label templates with your data tailored to your process help to reduce rework and improve visibility resulting in significant operational savings.

Consider taking a look at your own materials handling and inbound receiving process, and how it affects your inventory and overall efficiency. Is speed more important to you or cost savings? You may find that you’re spending an exorbitant amount of time and resources on something that can be dramatically improved by pushing labeling beyond your four walls. Do the math and see for yourself.

Take the first step to reevaluating your supplier labeling and talk to a Loftware specialist. We’ll look at your current process and discuss how an cloud-based labeling solution would fit in your environment and save you time and money. Every day you wait could be costing your company thousands of dollars in relabeling and excess inventory. Get in touch now!